Learn More

About Us

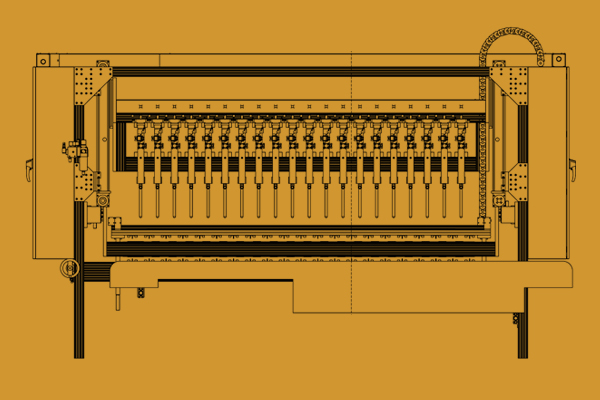

For more than two decades, TX Pocket Springs has been at the forefront of state-of-the-art bedding technology. Our commitment to quality, comfort, efficiency, and environmental friendliness requires constant innovation to always stay one step ahead of status quo—the GlueLess® Innerspring Assembler is a shining example of that philosophy.

A Timeline of our Rich History

Why the GlueLess® Innerspring Assembler?

Recyclability and Reliability Makes a World of Difference

TX Pocket Springs has been using the GlueLess® Innerspring Assembler for all its innersprings since 2017. The result has been the ability to produce a superior product that is consistently recognized by both the mattress manufacturers we supply and the mattress retailers and their customers for quality, comfort, efficiency, and environmental friendliness.

Social responsibility, worldwide environmental agencies, and ever-increasing landfills speak to the importance of totally recyclable products.