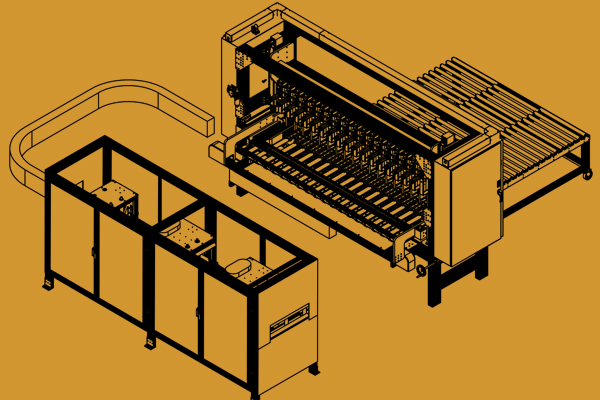

GLUELESS® INNERSPRING ASSEMBLER

Taking Automated Mattress Innerspring Production to a New Level

Eliminating Glue

While the industry standard calls for the use of glue throughout the production process, this patented disruptive technology instead fuses each coil together rather than using glue to produce the world’s first environmentally friendly pocket spring innerspring. We have found that eliminating glue has a myriad of benefits, including:

About Us

Bedding technology has evolved tremendously over the last two decades, and TX Pocket Springs has been there every step of the way. Our commitment to innovation and the enquiring minds of Martin Wolfson and his team of engineers, is the reason the disruptive technology of the GlueLess® Innerspring Assembler has become a reality.